2023-06-15

Tag Archives: high speed reduction gearbox

China high quality Hand operated small vertical gearbox slow speed WPS50 WPA50 reducer reduction for mixing near me supplier

WPA WPS WPO WPX WPDA WPDS WPOD WPDX WPKA WPKS WPWA WPWDX WPWK WPWDS WPDZ WORM GEAR REDUCER GEARBOX GEAR MOTORWP model 40~250 reducer model is made of cast iron cast in aluminum mould. The shape is beautiful and strong, and can be used through multi-directional Settings.WP series reducer, worm is made of 45 # high quality steel by heat treatment, and worm wheel is cast with tin bronze. It has good wear resistance, especially in bearing capacity. It is mainly suitable for deceleration transmission of various mechanical equipment such as plastics, metallurgy, beverage, mine, lifting and transportation, chemical construction and so on.

WPA Worm Reducer GearboxWPO Worm Reducer GearboxWPDA Worm Reducer Gearbox WPDO Worm Reducer GearboxWPX Worm Reducer GearboxWPS Worm Reducer Gearbox Speed Ratio1/101/151/201/251/301/401/501/60Efficiency77~90%76~88%75~84%72~82%68~82%64~75%62~72%60~71% There are many types of WP series reducer gearboxes, the ones shown above are the most. If you need to know more details about other models, please contact us. WP SERIES WORM GEAR SPEED REDUCERwp series structure drawing

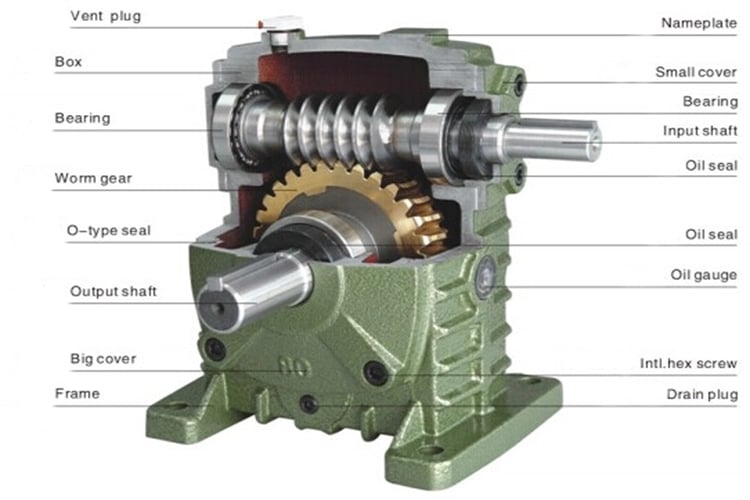

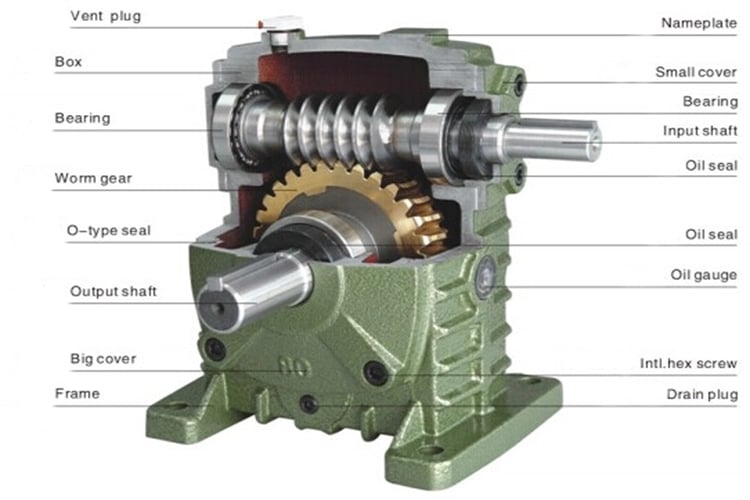

HIGH QUALITY OUTPUT SHAFTNew standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer.

PRECISION BEVEL GEAR20CrMn Ti material – low carbon alloy steelImported gear grinding machine processing, high hardness, CZPT 14inch 24V 48V 200RPM 200kg load 1571 encoder brushless AGV direct drive DC wheel hub servo motor for inspection robot stable performance.Vacuum CZPT carburizing heat treatment, carburizing layer uniform.

HIGH QUALITY SHELL MATERIAL20CrMn Ti material – low carbon alloy steelImported gear grinding machine processing, high hardness, stable performance.Vacuum CZPT carburizing heat treatment, carburizing layer uniform.

Mounting Dimension WP SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS OUTPUT SHAFT DIMENSIONS AND OVERVIEW DIMENSIONS

True evaluation from customers~Thank you for your trust and support. We will continue to provide you with the best products and services.In the future, we sincerely look forward to cooperating with you~ Company profile HangZhou YINXIN ELECTROMECHANICAL EQUIPMENT SUPPLY STATIONOur company is located in the city of HangZhou, ZheJiang Province of China. We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, FRONT AXLE CV AXLE DRIVE SHAFT AD-9571 1K0407272KA USED FOR GOLF A3 paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world. Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area WP series worm gear speed reducer It is mainly suitable for deceleration transmission of various mechanical equipment such as plastics, metallurgy, beverage, mine, lifting and transportation, chemical construction and so on.

Packing & Delivery PACKING AND TRANSPORTION●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ Q1: Are you a trading company or a manufacturer ?A: We are a manufacturer in ZheJiang Province, FORtoyota hiace gearbox parts 2TR2KD GEARBOX 12 Synchronizer assembly China. Our company owns the ability of manufacturing, processing, designing and R&D. We welcome your visit.Q2: How we select models and specifications?A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…Q3: How is your price? Can you offer any discount?A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.Q4: How long should I wait for the feedback after I send the enquiry?A4: We will reply as soon as possible, 12 hours at most.Q5: What is your product warranty period?A: We have the certifications of ISO9001,CE, SGS.Q6: What industries are your gearboxes being used?A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, Strong commercial twin shaft hard disk drive and solid state drive shredding machine tobacco equipment and so on.

How to Choose the Right Worm Shaft

You might be curious to know how to choose the right Worm Shaft. In this article, you will learn about worm modules with the same pitch diameter, Double-thread worm gears, and Self-locking worm drive. Once you have chosen the proper Worm Shaft, you will find it easier to use the equipment in your home. There are many advantages to selecting the right Worm Shaft. Read on to learn more.

Concave shape

The concave shape of a worm’s shaft is an important characteristic for the design of a worm gearing. Worm gearings can be found in a wide range of shapes, and the basic profile parameters are available in professional and firm literature. These parameters are used in geometry calculations, and a selection of the right worm gearing for a particular application can be based on these requirements.

The thread profile of a worm is defined by the tangent to the axis of its main cylinder. The teeth are shaped in a straight line with a slightly concave shape along the sides. It resembles a helical gear, and the profile of the worm itself is straight. This type of gearing is often used when the number of teeth is greater than a certain limit.

The geometry of a worm gear depends on the type and manufacturer. In the earliest days, worms were made similar to simple screw threads, and could be chased on a lathe. During this time, the worm was often made with straight-sided tools to produce threads in the acme plane. Later, grinding techniques improved the thread finish and reduced distortions resulting from hardening.

When a worm gearing has multiple teeth, the pitch angle is a key parameter. A greater pitch angle increases efficiency. If you want to increase the pitch angle without increasing the number of teeth, you can replace a worm pair with a different number of thread starts. The helix angle must increase while the center distance remains constant. A higher pitch angle, however, is almost never used for power transmissions.

The minimum number of gear teeth depends on the angle of pressure at zero gearing correction. The diameter of the worm is d1, and is based on a known module value, mx or mn. Generally, larger values of m are assigned to larger modules. And a smaller number of teeth is called a low pitch angle. In case of a low pitch angle, spiral gearing is used. The pitch angle of the worm gear is smaller than 10 degrees.

Multiple-thread worms

Multi-thread worms can be divided into sets of one, two, or four threads. The ratio is determined by the number of threads on each set and the number of teeth on the apparatus. The most common worm thread counts are 1,2,4, and 6. To find out how many threads you have, count the start and end of each thread and divide by two. Using this method, you will get the correct thread count every time.

The tangent plane of a worm’s pitch profile changes as the worm moves lengthwise along the thread. The lead angle is greatest at the throat, and decreases on both sides. The curvature radius r” varies proportionally with the worm’s radius, or pitch angle at the considered point. Hence, the worm leads angle, r, is increased with decreased inclination and decreases with increasing inclination.

Multi-thread worms are characterized by a constant leverage between the gear surface and the worm threads. The ratio of worm-tooth surfaces to the worm’s length varies, which enables the wormgear to be adjusted in the same direction. To optimize the gear contact between the worm and gear, the tangent relationship between the two surfaces is optimal.

The efficiency of worm gear drives is largely dependent on the helix angle of the worm. Multiple thread worms can improve the efficiency of the worm gear drive by as much as 25 to 50% compared to single-thread worms. Worm gears are made of bronze, which reduces friction and heat on the worm’s teeth. A specialized machine can cut the worm gears for maximum efficiency.

Double-thread worm gears

In many different applications, worm gears are used to drive a worm wheel. These gears are unique in that the worm cannot be reversed by the power applied to the worm wheel. Because of their self-locking properties, they can be used to prevent reversing motion, although this is not a dependable function. Applications for worm gears include hoisting equipment, elevators, chain blocks, fishing reels, and automotive power steering. Because of their compact size, these gears are often used in applications with limited space.

Worm sets typically exhibit more wear than other types of gears, and this means that they require more limited contact patterns in new parts. Worm wheel teeth are concave, making it difficult to measure tooth thickness with pins, balls, and gear tooth calipers. To measure tooth thickness, however, you can measure backlash, a measurement of the spacing between teeth in a gear. Backlash can vary from one worm gear to another, so it is important to check the backlash at several points. If the backlash is different in two places, this indicates that the teeth may have different spacing.

Single-thread worm gears provide high speed reduction but lower efficiency. A multi-thread worm gear can provide high efficiency and high speed, but this comes with a trade-off in terms of horsepower. However, there are many other applications for worm gears. In addition to heavy-duty applications, they are often used in light-duty gearboxes for a variety of functions. When used in conjunction with double-thread worms, they allow for a substantial speed reduction in one step.

Stainless-steel worm gears can be used in damp environments. The worm gear is not susceptible to rust and is ideal for wet and damp environments. The worm wheel’s smooth surfaces make cleaning them easy. However, they do require lubricants. The most common lubricant for worm gears is mineral oil. This lubricant is designed to protect the worm drive.

Self-locking worm drive

A self-locking worm drive prevents the platform from moving backward when the motor stops. A dynamic self-locking worm drive is also possible but does not include a holding brake. This type of self-locking worm drive is not susceptible to vibrations, but may rattle if released. In addition, it may require an additional brake to keep the platform from moving. A positive brake may be necessary for safety.

A self-locking worm drive does not allow for the interchangeability of the driven and driving gears. This is unlike spur gear trains that allow both to interchange positions. In a self-locking worm drive, the driving gear is always engaged and the driven gear remains stationary. The drive mechanism locks automatically when the worm is operated in the wrong manner. Several sources of information on self-locking worm gears include the Machinery’s Handbook.

A self-locking worm drive is not difficult to build and has a great mechanical advantage. In fact, the output of a self-locking worm drive cannot be backdriven by the input shaft. DIYers can build a self-locking worm drive by modifying threaded rods and off-the-shelf gears. However, it is easier to make a ratchet and pawl mechanism, and is significantly less expensive. However, it is important to understand that you can only drive one worm at a time.

Another advantage of a self-locking worm drive is the fact that it is not possible to interchange the input and output shafts. This is a major benefit of using such a mechanism, as you can achieve high gear reduction without increasing the size of the gear box. If you’re thinking about buying a self-locking worm gear for a specific application, consider the following tips to make the right choice.

An enveloping worm gear set is best for applications requiring high accuracy and efficiency, and minimum backlash. Its teeth are shaped differently, and the worm’s threads are modified to increase surface contact. They are more expensive to manufacture than their single-start counterparts, but this type is best for applications where accuracy is crucial. The worm drive is also a great option for heavy trucks because of their large size and high-torque capacity.

Best China manufacturer & factory china supplier 1:30 1:40 ratio variable speed bevel gear 90 degree bevel gearbox reduction for sale Conveyor With high quality best price

EPG has been successfully certified by ISO9002 Quality Management System, ISO9001 Quality Management System, API certificate, ISO/TS16949:2002 and ISO10012 measurement management system.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Model Number:

-

B3SH B2SH VH 13-26

- Rated Power:

-

1.5~6229KW(customized)

- Pole:

-

single stage two stage three stage

- Ratio:

-

2.8-2000

- Housing Material:

-

Cast Iron

- Material:

-

20CrMnTi

- Working temperature:

-

-40~45℃

- Type:

-

variable speed bevel gear 90 degree bevel gearbox reduction for sale

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

92%~96%

Supply Ability

- Supply Ability:

- 5000 Set/Sets per Year variable speed 90 degree bevel gearbox reduction for sale convey

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for 1:30 1:40 ratio variable speed bevel gear 90 degree bevel gearbox reduction for sale Conveyor

- Port

- Qingdao

Online Customization

Product Description

H B Series Industrial GearBox

Ever-Power Machinery —— Tianqi Brand Industrial gearbox manufacturers/Gear Box Transmission

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

Specification

H B Series Gearbox Reducer:

(please contact us for more types & model)

| Type | n r/min |

Transmission Ratio (i) |

Type | n r/min |

Transmission Ratio (i) |

Type | n r/min |

Transmission Ratio (i) |

Type | n r/min |

Transmission Ratio (i) |

| H1SH | 750 | 1.25-2 | H2 B2 | 750 | 5-9 | H3 B3 | 750 | 12.5-112 | H4 B4 | 750 | 80-450 |

| 2.24-5.6 | 10-28 | 1000 | 12.5-112 | 1000 | 80-450 | ||||||

| 1000 | 1.25-2 | 1000 | 5-9 | 1500 | 12.5-31.5 | 1500 | 80-112 | ||||

| 2.24-5.6 | 10-28 | 35.5-56 | 125-450 | ||||||||

| 1500 | 1.25-2 | 1500 | 5-6.3 | 63-112 | |||||||

| 4-5.6 | 7-9 | ||||||||||

| 10-16 | |||||||||||

| 18-28 | |||||||||||

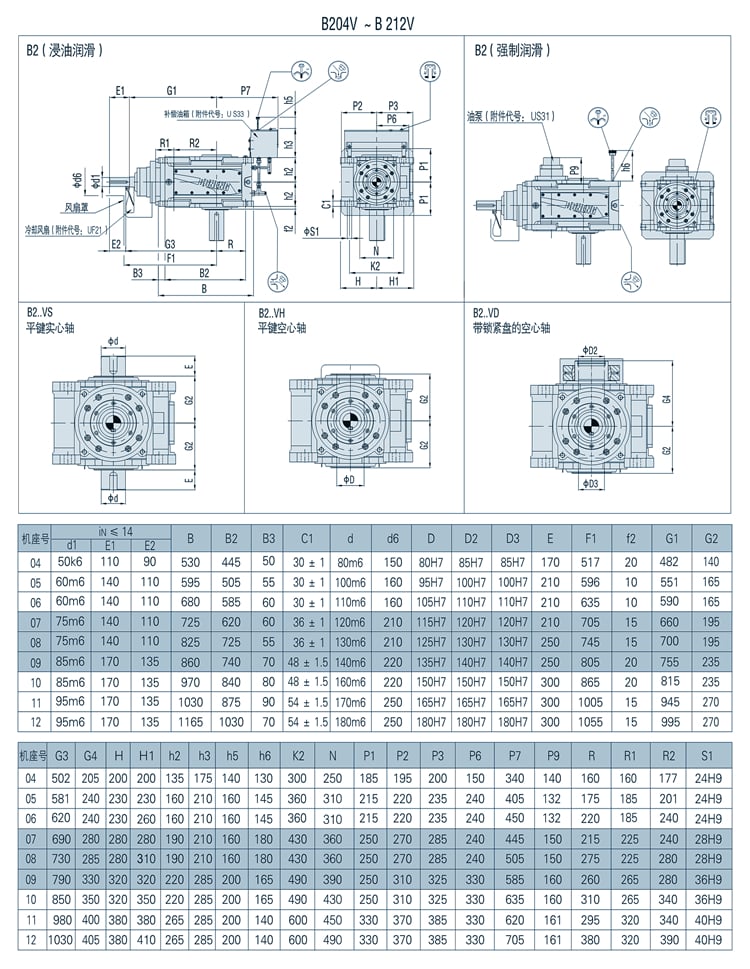

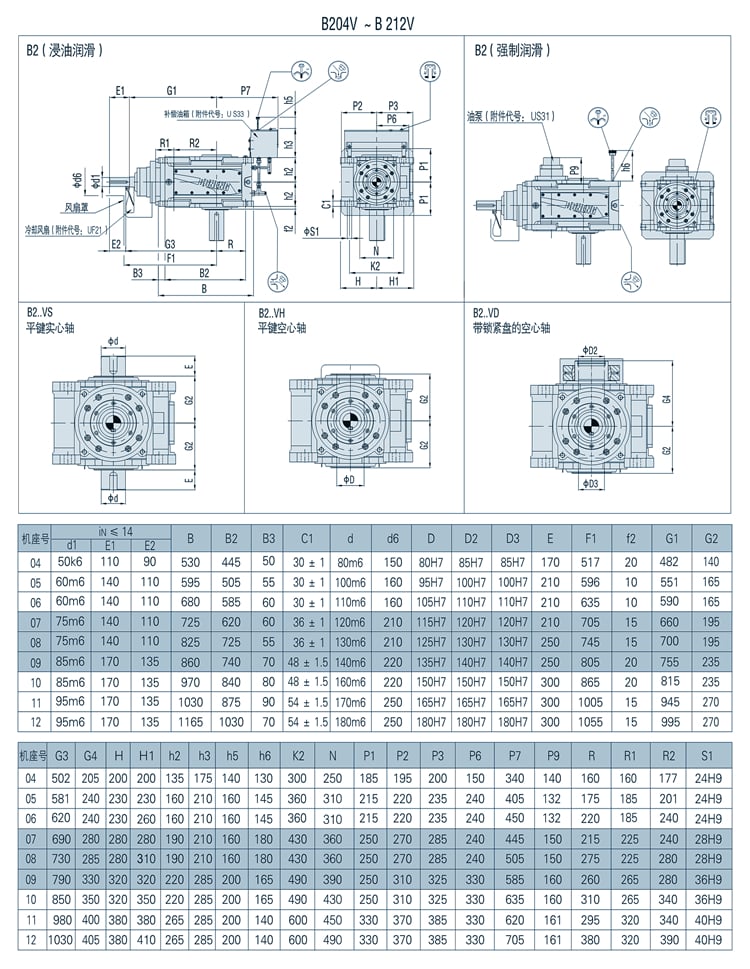

Mounting Diamensions:

Model selection for Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.H B series standard industrial gear box reducer.Industrial Right Angle Transmission Gearbox price.Gearbox Manufacturer helical gear design gearbox with moderate price.HB Bevel helical gearbox for water treatment.Chinese Gearbox Manufacturer H B Series Industrial Gear Box Reducer.High Torque H B Helical gearbox for hauling winches..H B Helical High rpm Reduction Gearbox price for conveyors 1:40 ratio.High precision H B series industrial heavy duty gear gearbox speed reducer.right angle spiral bevel gearbox prices for lifting cranes.right angle 5: 1 ratio gearbox reduction gearbox prices for extruders and mixers.drill speed reducer gearbox speed increaser for Dredging Equipments.90 degree transmission gearbox for amusement park equipment stage equipment.1:30 1:40 ratio variable speed bevel gear 90 degree bevel gearbox reduction for sale Conveyor.

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

Feature:

-

Realized parallel shaft,right-angle shaft modes and horizontal,vertical mounting modes. Using less component parts.

-

Applying advanced grinding process which improved the stability and the efficiency of transmit power with lower noise.right angle 5: 1 ratio gearbox reduction gearbox prices for extruders and mixers.

-

Input mode: motor connected flange, shaft input.Reduction ratio B series Cycloid Speed Reducer Gearbox.

-

Output mode:solid shaft with flat key,hollow shaft with flat key,hollow shaft with shrink disk,hollow shaft with spline connection, solid shaft with spline connection, solid shaft with flange.

-

Mounting mode:vertical, horizontal, swing base-mounted, torque-arm-mounted.

-

Ratio range:1.23~450. It can be higher when combining with K&R series reducer. H B series standard industrial gear box reducer.Industrial Right Angle Transmission Gearbox price.Gearbox Manufacturer helical gear design gearbox with moderate price.HB Bevel helical gearbox for water treatment.Chinese Gearbox Manufacturer H B Series Industrial Gear Box Reducer.High Torque H B Helical gearbox for hauling winches.H B Series Helical gearbox for bucket elevators.H B Helical High rpm Reduction Gearbox price for conveyors 1:40 ratio.High precision H B series industrial heavy duty gear gearbox speed reducer.variable speed 90 degree transmission bevel gearbox reduction for Conveyor.

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.100: 1 ratio gearbox.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.Industrial Right Angle Transmission Gearbox price.Gearbox Manufacturer helical gear design gearbox with moderate price.HB Bevel helical gearbox for water treatment.Chinese Gearbox Manufacturer H B Series Industrial Gear Box Reducer.High Torque H B Helical gearbox for hauling winches.H B Series Helical gearbox for bucket elevators.washing machine H B Helical gear box price for hauling winches and conveyors.H B Helical High rpm Reduction Gearbox price for conveyors 1:40 ratio.3: 1 ratio gearbox.1:30 ratio gearbox.High precision H B series industrial heavy duty gear gearbox speed reducer.right angle spiral bevel gearbox prices for lifting cranes.right angle 5: 1 ratio gearbox reduction gearbox prices for extruders and mixers.drill speed reducer gearbox speed increaser for Dredging Equipments.90 degree transmission gearbox for amusement park equipment stage equipment.Reduction ratio B series Cycloid Speed Reducer Gearbox.1:30 1:40 ratio variable speed bevel gear 90 degree bevel gearbox reduction for sale Conveyor.

Packaging & Shipping

- 1. Big Volecity- Reducing Ratio:Ratio of singleWe designed, especially for our customers, a protective cone which is flexible and enables easier handling while coupling the PTO on the tractor or working machine. The flexible cone offers additional comfort when coupling the PTO, because you can get a good grip in the limited shaft space.-stage speed-reducing is 1/11-1/87; Ratio of double stage speed-reducing is 1/112-1/5133;Ratio of three-stage speed-reducing is 1/2057-1/446571;more-stages can be cThe company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc. ombined according to the requirement.

-

2. High Accudrive Servo Gearheads Servo drives from EPG Drive benefit from the expertise and innovation of our more traditional brands. Available in both right angle and inline configurations, coupled with the availability of multiple precision levels, you are sure to find the right product for your application.EPG Drive Accudrive Servo Gearheaddriving efficiency:Due to adopting rolling engagement in falling-in part, the driving efficiency can reach above 90%.

-

3. Small in size, light weight: with compacted structure,small size and light weight. Due to adopting the principle of planet driving so that the input and output shaft in the same axis which will integrated with the motor.

-

4. Long service life: Has good resistance to abrasion because the main driving engaging parts are made of bearing steel and applying rolling friction.

-

5. Stable running: for most driving procedure, we adopt multi-teeth falling-in. Then the running will be stable with low noise.Reduction ratio B series Cycloid Speed Reducer Gearbox.

-

6. Convenient dismounting:reasonable structure and design.

-

7. Strong overloading ability,anti-compact,suitable for frequently start and double-side rotation.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!