Product Description

Product Description

|

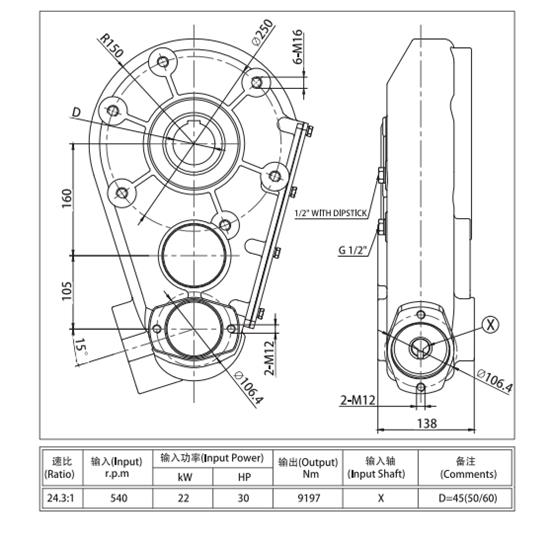

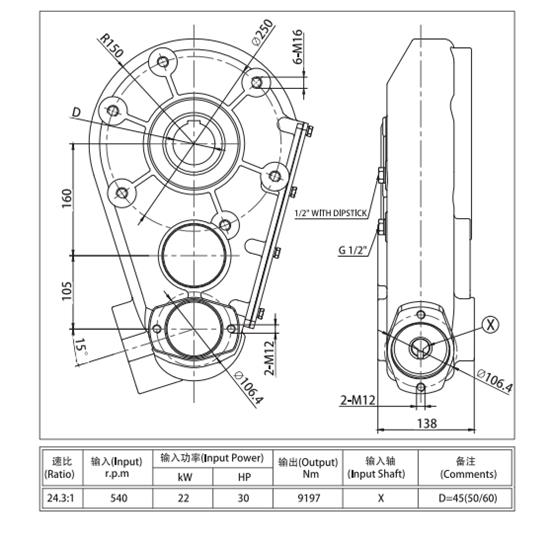

Item No.: |

C67, Cast Iron Housing Triple Gearbox |

|

Ratio and Shaft: |

OEM acceptable |

|

Key word |

Agricultural Machinery Gearbox |

Company Profile

HangZhou Hengni Machinery Co., Ltd. was founded in 2571 by Ms. Iris and her 2 partners (Mr. Tian and Mr. Yang) in HangZhou City, ZHangZhoug Province, China. All 3 founders are average senior engineers. Due to business expansion, the company moved to its current location in Xihu (West Lake) Dis. Industrial Zone (HangZhou, ZHangZhoug Province, China) in 2014.

We specialize in a full line of spiral bevel gearboxes, spur gearboxes, spur gearboxes, drive shafts, sheet metal, hydraulic cylinders, motors, tires, worm gear reducers, and worm operators, providing solutions for agricultural machinery manufacturers and distributors worldwide. All products can be customized on request.

We have a complete quality management system and sales and service network to provide our customers with quality products and satisfactory services. Our products are sold to 36 countries and regions around the world and our main market is the European market.

Factory & Workshop

Proffessional

30 years experience engineman. The R&D office, Test laboratory, and CNC lathe workshop are operated by professionals.

Responsible

2~10years warranty. Attitude determines everything, details determine success or failure. We are responsible for your products.

Scientific management

100% tested. Strict company systems and scientific material management will reduce the error rate.

Certifications

We have been researching and manufacturing a wide range of gearbox reducers and mechanical components. We have obtained certificates including ISO9001, several gearbox patents, SGS, BV, etc.

Sample Room

Why choose us?

1) Customization: With a strong R&D team, and we can develop products as required. It only takes up to 7 days for us to design a set of drawings. The production time for new products is usually 50 days or less.

2) Quality: We have our own complete inspection and testing equipment, which can ensure the quality of the products.

3) Capacity: Our annual production capacity is over 500,000 sets, also, we also accept small quantity orders, to meet the needs of different customer’s purchase quantities.

4) Service: We focus on offering high-quality products. Our products are in line with international standards and are mainly exported to Europe, Australia, and other countries and regions.

5) Shipment: We are close to HangZhou and ZheJiang ports, to provide the fastest shipping service.

FAQ

Q: Are you a trading company or manufacturer?

A: We’re factory and providing gearbox ODM & OEM services for the European market for more than 10 years

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time? What is your terms of payment?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization.

For standard products, the payment is: 30% T/T in advance,balance before shipment.

Q: What is the exact MOQ or price for your product?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.

Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | for Hydraulic Motor |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Is a worm gear reducer gearbox right for your application?

If you’re interested in gear reduction and wondering if a worm gear reducer gearbox is right for your application, you’ve come to the right place. This gear reducer gearbox is efficient and compact. In addition, it has small clearances and is easy to install. Let’s take a closer look.

This is a reducer gearbox

Worm reducer gearbox is a type of reduction gear used in machinery. This gear reduces the output speed by changing the ratio of input to output. Gears come in a wide range of sizes and can be made from a variety of materials, including aluminum, cast iron, and stainless steel. Its efficiency depends on the ratio and size of the gears. It is usually used in low speed applications. But it can also be used as an auxiliary braking device for high-speed moving machinery.

When choosing a reduction gear, it’s important to look for models with multiple teeth. Ideally, it will have more teeth than the corresponding sprocket. This will reduce the noise produced by the gears. The maximum number of teeth of the worm gear should be greater than 40.

Worm gears produce less noise and vibration than conventional gears. Also, they are cheaper and smaller than other types of reduction gears. However, worm gears have some limitations that make them less efficient than other types. For example, they do not perform as efficiently as parallel or orthogonal axes, which are much better at transmitting power.

The main disadvantage of worm gears is the difficulty of lubrication. Worm gear reducer gearboxes require more lubrication due to the helical motion of the gears. This means it is less efficient and more prone to wear than a standard gearbox. Helical motion has problems transmitting power and causes sliding friction, also known as sliding wear.

A worm reducer gearbox is a reduction gearbox used to decelerate a high-speed motor to a low-speed output. Worm gear reducer gearboxes produce lower output speeds while maintaining high torque. Its gears are made of bronze or stainless steel and have a right-angle output. The gears are very small compared to other reducer gearboxes, so they can be used in tight spaces and applications where space is limited.

Worm gear reducer gearboxes are an excellent choice for applications requiring high torque and low speeds. These reducer gearboxes are compact, durable and have a long service life. These gearboxes are also compatible with solid and hollow output shafts. This feature eliminates the need for chains or belts, reducing the number of moving parts. Plus, they’re easy to maintain, which means they’re an excellent choice for a variety of applications.

Worm gear reducer gearboxes are also compact, versatile and easy to install. The worm gear itself is made from a single piece of alloy steel. It has a high helix angle and is case hardened and ground for durability. Its six AF hex sockets are designed for easy installation and a wide range of ratios. Worm gear reducer gearboxes are also suitable for manual operation. They are easy to install, compact in design and compatible with a wide range of motors and drives.

Worm reducer gearboxes are often used in industrial settings where a small amount of torque is required to move large objects. They are also useful when space is at a premium. They are compact and easy to install in tight spaces. Worm gears reduce the risk of tripping and are often made of durable materials, making them a popular choice.

Compared with planetary gearboxes, worm gear reducer gearboxes have many advantages. They are quiet, produce less noise, and are more comfortable to use. They are also more energy efficient than their planetary counterparts. Furthermore, they can be combined with other gearboxes and trains to increase their output efficiency.

It is high efficiency

When a worm reducer gearbox is used in a gear-motor, it is critical to note that it is extremely high in efficiency. This type of reducer gearbox is typically much hotter than a hypoid reducer gearbox, which reduces the service life of the gear. The increased thermal stress on the sliding gears results in premature seal wear and leakage. Furthermore, excessive heat causes lubrication to break down and can cause contamination. Helical gear reducer gearboxes are significantly cooler and have a low-maintenance design. Consequently, they can reduce factory downtime and energy costs.

A servo-worm reducer gearbox is an excellent choice for applications requiring high performance, repeatability, and precision positioning. These gear reducer gearboxes have been specifically designed for use with servo motor technology, which provides tight integration of the gear motor. Other advantages of a servo-worm reducer gearbox include reduced angular backlash and longer life.

Hypoid gearmotors offer increased efficiency and allow smaller motors to be used. A 1 HP worm reducer gearbox can produce the same amount of output as a 1/2 HP hypoid reducer gearbox. A Agknx study compared the two types of reducer gearboxes, comparing power, torque, and efficiency. As a result, a 1/2 HP hypoid gearmotor is much cheaper to operate than a 1 HP worm reducer gearbox.

The efficiency of a worm gear reducer gearbox depends on many factors, including the mesh of the gears and losses in the bearings and oil seal lips. The speed and load of the reducer gearbox also have an impact on its efficiency. As a result, worm gear reducer gearboxes should be used with the right type of lubricant.

In a worm gear reducer gearbox, a non-intersecting shaft rotates against a gear, while the output worm gear rotates in a perpendicular direction. This arrangement produces high efficiency while reducing the noise and vibration of the gear motor. This gear reducer gearbox is also quiet and has a low friction coefficient.

It has a low clearance

Worm reducer gearboxes are typically designed with a low clearance, meaning that the worm is not allowed to touch the wheels in the gear arrangement. The lubricant used depends on the size of the gearing, and it is usually ISO 680 or ISO 460. Higher viscosities require special equipment.

Worm gears are popular in machines that need to stop quickly, such as lifts and elevators. The gears and worm are made of a soft material, minimizing backlash and failure rates. They are also popular in heavy-duty machines, such as rock crushers. But while this is an important aspect of their design, there are other factors to consider when choosing a worm gear.

Worm gears have multiple teeth, which allows for greater surface area contact and a better distribution of load. This feature allows for high transmission ratios without sacrificing power. Worm gears can be paired with other gearboxes to increase the overall efficiency of the system.

Worm gears are often used in heavy machinery, including trucks barreling down a deserted highway. They can also be found in packaging machinery, conveyors, and other small machinery. Their unique shape makes them ideal for tight spaces. But they also tend to wear and tear much faster than conventional gears.

It has a high torque to weight ratio

The worm gear reducer gearbox is a versatile gear train that provides a high torque-to-weight ratio. These reducer gearboxes are typically used in applications that require high torque and high gear ratios, such as machine tools. They also have a very compact design, enabling very high gear ratios at low speeds.

Worm gear reducer gearboxes are very quiet, mainly because the input and output shafts are perpendicular to each other. Their low noise level is an advantage compared to planetary gearboxes. Compared with planetary reducer gearboxes, worm gear reducer gearboxes are also relatively cheap.

The worm gear consists of two parts: the helical butt-jointed worm gear and the worm. The screw-butted worm gear is connected to the shaft by a helical thread. The worm gear is a variation of the six-simple machine. The worm is located in the worm wheel, which forces the worm to rotate. It also changes the plane of motion. Worm gears are usually made of steel or brass.

Worm gear reducer gearboxes are one of the most popular types of reducer gearboxes. It provides high torque and high speed ratio in a compact package. These reducer gearboxes are used in many power transmission systems, including elevators, safety gates, conveyor belts, and medical testing equipment.

Worm reducer gearboxes come in a variety of shapes and sizes, including parallel shaft reducer gearboxes and planetary worm reducer gearboxes. They have a high torque-to-weight ratio and are easy to maintain. They are also lightweight and relatively easy to install. This makes them an excellent choice for many applications.

Worms can be assembled using stepped shafts, set screws or dowel pins. However, the worm is subject to a lot of thrust and must be held firmly. This could lead to a rebound. Also, the bearings may come loose and the worm may move. To avoid backlash, make sure the worm gear shaft passes through the midpoint of the worm face width.

editor by CX 2023-05-25

China high quality Agricultural Snow Plow Gearbox for Spreader Ep-01-229 1: 1.35 aluminum worm gearbox

Product Description

Product Description

If the gearbox on your snow plow has been damaged, replace it with this gearbox. This gearbox replaces #322.002 and will have your snow plow like new again.

Product Parameters

| ITEM | EP-01-229 |

| Ratio | 1:1.35 |

| Teeth | 16/16 |

| Module | 4.5 |

| Power(HP) | – |

| Rated Input | 540rpm |

| Input/Output description | 1 3/8 Z6 φ25 Optic axis |

| Weight(N.W) | 13Kg |

Company Profile

HangZhou Ever-power Transmission Machinery Co., Ltd. was established in 2006. The company is located in ZHangZhoug HangZhou, with 90 employees, an area of 3800 meters, and an annual output value of 40 million yuan. The company is committed to the R & D, manufacturing, and personnel training of various gearboxes, reducers, and construction machinery, including spiral bevel gearbox, spur gearbox, worm gearbox, and cylindrical gearbox. It also includes a variety of high-pressure cast valve body and shell products. Its products are used in various applications, such as agricultural mowers, snow sweepers, fertilizer applicators, grain conveyors, industrial equipment, oil mining machinery, marine industrial equipment, and engineering hydraulic components. More than 95% of its products are exported to Europe, the United States, and Australia. Asia and Canada. The company has strong technology and R & D capabilities, produces reliable and high-quality products, pursues a unique business philosophy and enjoys a high reputation in the manufacturing industry. Welcome to contact us by phone or email.

Our Equipments

Certification

Packaging and Shipment

Related products

PTO Shaft

Agricultural gearbox:

Flail mower gearbox, rotary tiller gearbox, lawn mower gearbox, rotary cutter gearbox, agricultural sprayer gearbox, post hole digger gearbox, feed mixer gearbox, rotary mower gearbox, gearbox for circular saws, irrigation reels gearbox, agricultural generator gearbox, fertilizer spreader gearbox, hydraulic drive gearbox, manure spreader gearbox, rotary rakes gearbox, hay tedders gearbox, micro tiller gearbox, cutter bars gearbox, fertilizer mixer gearbox, agitators gearbox for sewage, round baler gearbox, snowblower gearbox

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Soft Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

A-Drive PWC single worm reducer gearbox

A worm gear is a gear used to reduce the speed of a mechanical device. Often used in the automotive and shipbuilding industries, these gears have a lifespan comparable to many other types of reducer gearboxes. As a result, worm gears continue to be popular with engineers.

Agknx driver

Conical drive worm reducer gearboxes are an excellent choice for a variety of applications. The double-enveloping worm gear geometry of the Agknx Drive reducer gearbox provides a larger contact area and higher torque carrying capacity. This specialized gear system is also ideal for applications requiring higher precision.

Agknx Drive’s products are ideal for the solar, packaging, steel, food and pulp and paper industries. Additionally, Agknx Drive’s products are ideal for motion control and medium to heavy duty applications. The company’s dedicated sales and service teams are available to assist with your specific needs.

Agknx drive worm gear reducer gearboxes are available in single, double and triple reductions. Depending on the application, a single stage unit can transport up to 7,500 lbs. of torque. Its low-cost, compact design makes it a convenient option. Conical drive gearboxes are versatile and durable.

X & H

X & H worm gear units feature worm gear sets and are available in two different series. The X-Series includes XA versions with shaft and XF to XC versions with motor mounts. Compared to the XC compact series, the XF series offers outstanding versatility and higher efficiency. The H series combines the features of the X series with a spur gear pre-stage on the input. The H series has a die cast aluminum housing and cast iron shaft.

The X & H Worm reducer gearbox Series “H” helical gears are compatible with NMRV and C side input 56F wired motors. These gear reducer gearboxes are low cost and easy to install. They feature a cast iron housing and four threaded mounting holes.

RV seriese aluminum right angle

RV seriese aluminum right angle worm reduces versatility and durability. They are available in a variety of sizes including 25, 30, 40, 50, 63, 75, 110, 130, 150. Featuring standard NEMA motor input flanges and torque arm or foot mounting options, these reducer gearboxes are ideal for a variety of applications.

RV series worm gear reducer gearbox is made of high-quality aluminum alloy with compact structure. It also features light weight, corrosion resistance and low noise. Its housing is made of die-cast aluminum alloy, while the worm gear is made of 20CrM. The worm gear is heat treated by carbon quenching to increase its hardness. The thickness of the carbide layer is between 0.3-0.5mm.

These worm gear reducer gearboxes have multiple functions to maximize efficiency. In addition to being corrosion resistant, they are available in a variety of sizes to suit any application. Other features include a corrosion-resistant cast iron housing, enclosed breather, double-lip seal and magnetic drain plug. These worm gear reducer gearboxes are available with single or dual input shafts and are interchangeable with NMRVs.

Aluminum alloy right angle worm reducer gearbox is a light, durable and efficient gear reduction device. Its compact design makes it lighter than other gearheads, while its rust-resistant surface and long life make it an excellent choice for industrial and automotive applications. It is available in a variety of sizes, including inches. AGknx Single

AGknx Single

Worm reducer gearboxes can be classified as sacrificial gears. It is used to reduce the torque of the machine. It has two parts: a worm and wheels. The worm can be made of brass or steel. Brass worm gears corrode easily. Phosphorus EP gear fluid can run on brass worm gears. It creates a thin oxide layer on the gear teeth, protecting them from impact forces and extreme mechanical conditions. Unfortunately, it can also cause serious damage to the brass wheels.

Worm reducer gearboxes work by transferring energy only when the worm is sliding. This process wears away the lubricating layer and metal of the wheel. Eventually, the worm surface reaches the top of the wheel and absorbs more lubricant. This process will repeat itself in the next revolution.

Worm reducer gearboxes have two benefits: they are compact and take up little space. They can slow down high-output motors while maintaining their torque. Another important feature of the worm gear reducer gearbox is its high transmission ratio capability. It can be installed in both vertical and horizontal positions, and a bidirectional version is also available.

Worm gears have some complications compared to standard gear sets, but overall they are reliable and durable. Proper installation and lubrication can make them sturdy, efficient devices.

A-Drive AGknx Single

If you’re considering purchasing a new worm gear reducer gearbox for your A-Drive AGknx single, you need to understand your goals. While single-stage worm reducer gearboxes can be used, their reduction ratios are often limited. In most cases, they can only achieve a reduction ratio of 10:1. However, there are other types of gears that provide additional speed reduction capabilities.

The worm reducer gearbox consists of two parts: the input worm and the output worm. Each component has its own rotational speed, the input worm rotates in a single direction and the output worm wheel rotates vertically. In a five-to-one ratio, the input worm rotates five times for each output worm. Likewise, a 60-to-1 ratio requires 60 revolutions of each worm. Due to this arrangement, the worm reducer gearbox is inefficient. Gear reduction is inefficient due to sliding friction rather than rolling friction.

Worm reducer gearboxes are also susceptible to thermal stress. They run hotter than hypoid reducer gearboxes, which reduces their useful life. In addition to higher heat, worm reducer gearboxes can experience component failure over time. In addition, an oil change is imminent due to the deterioration of lubrication.

The worm gear reducer gearbox of the A-Drive PPC single is a direct drive gearbox for personal watercraft. It has bronze bushings, aluminum gears, and a spool box. The spool box has a quarter-inch plated spool to wrap 1/4-inch 7 x 19 aircraft cable. Its design also makes it a more efficient alternative to belt-driven AGknx cranes. AGknx X & H

AGknx X & H

The AGknx X & H worm gear reducer gearbox series is a high-performance universal mount worm gear reducer gearbox. It features a spur gear primary on the input for higher performance and a wider range of gear ratios. Its design also allows it to be used with a variety of input shaft types, including shaft and closed-coupled applications.

It is available in a variety of sizes, including popular frame sizes 90 and 110. The worm shaft is made of case-hardened alloy steel with a cast iron hub and bronze ring gear. The standard output shaft is hollow. There are also models with dual single-shaft outputs.

editor by CX 2023-05-16

China ND High Quality Agricultural Gearbox for Manure Spreader (C67) gearbox worm box

Item Description

Item Description

|

Product No.: |

C67, Forged Iron Housing Triple Gearbox |

|

Ratio and Shaft: |

OEM acceptable |

|

Essential phrase |

Agricultural Machinery Gearbox |

Business Profile

In 2571, HangZhou CZPT Equipment Co.,ltd was recognized by Ms. Iris and her 2 companions(Mr. Tian and Mr. Yang) in HangZhou City, ZHangZhoug province, China, all 3 Founders are engineers who have much more than averaged thirty several years of knowledge.

We, CZPT machinery proven a total good quality administration method and revenue provider network to supply customers with higher-quality items and satisfactory support. Our goods are marketed in 36 countries and areas in the planet, our principal marketplace is the European marketplace.

Manufacturing unit & Workshop

Professional

30 several years expertise engineman. R&D workplace, Examination laboratory, CNC lathe workshop operated by specialists.

Accountable

two~10years guarantee. Frame of mind establishes everything, information figure out accomplishment or failure. We are liable for your items.

Scientific administration

a hundred% tested. Strict firm program and scientific materials administration will minimize the mistake charge.

Certifications

We are functioning on research and production all kinds of gearbox reducer and mechanical elements these 11 years, and have attained certificates which includes ISO9001, many Gearbox Patents, SGS, BV, and so on.

Sample Area

Through our CZPT brand name ND, CZPT Equipment provides agricultural options to agriculture machinery producer and distributors CZPT by way of a full line of spiral bevel / straight bevel / spur gearboxes, push shafts, sheet metal, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators and so forth. Merchandise can be personalized as ask for.

FAQ

Q: Are you investing firm or manufacturer ?

A: We are specifically a factory.

Q: Do you give samples ? is it free of charge or extra ?

A: Sure, we could supply the sample for cost-free charge but do not spend the expense of freight.

Q: How extended is your shipping time ? What is your terms of payment ?

A: Usually it is 40-forty five days. The time might fluctuate based on the merchandise and the stage of customization. For regular merchandise, the payment is: 30% T/T in progress, equilibrium prior to shippment.

Q: What is the precise MOQ or cost for your merchandise ?

A: As an OEM firm, we can give and adapt our products to a vast variety of needs.Therefore, MOQ and cost might drastically range with size, substance and more technical specs For instance, pricey items or normal goods will generally have a lower MOQ. Remember to speak to us with all relevant information to get the most correct quotation.

If you have yet another question, make sure you really feel totally free to get in touch with us.

|

/ Piece | |

50 Pieces (Min. Order) |

###

| Application: | Motor, Machinery, Agricultural Machinery, Fertilizer Spreader |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Shaft T and L Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Single-Step |

###

| Samples: |

US$ 1500/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

|

Item No.:

|

C67, Cast Iron Housing Triple Gearbox

|

|

Ratio and Shaft:

|

OEM acceptable

|

|

Key word

|

Agricultural Machinery Gearbox

|

|

/ Piece | |

50 Pieces (Min. Order) |

###

| Application: | Motor, Machinery, Agricultural Machinery, Fertilizer Spreader |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Shaft T and L Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Single-Step |

###

| Samples: |

US$ 1500/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

|

Item No.:

|

C67, Cast Iron Housing Triple Gearbox

|

|

Ratio and Shaft:

|

OEM acceptable

|

|

Key word

|

Agricultural Machinery Gearbox

|

What is a worm gear reducer gearbox?

The worm gear reducer gearbox is used to change the output speed of the mechanical device. It consists of worm and helical gears mounted on the input side of the equipment. In some cases, this gear reduction system can be multi-stage, enabling extremely low output speeds. It has the advantages of low energy consumption and low vibration. Hollow shaft worm gear reducer gearbox

Hollow shaft worm gear reducer gearbox

Worm gear reducer gearbox is an effective device to reduce the speed of mechanical equipment. The use of hard steel or non-ferrous metals for the worm increases its efficiency. Worms made of hard steel generate more heat than worms made of mild steel. Different thermal expansion results in gaps between mating surfaces. Despite its many benefits, worm gear reducer gearboxes are prone to oil leakage, which can be a problem for a number of reasons.

Hollow shaft worm gear reducer gearboxes are available in different gear ratios and are compatible with many motor types. Some are available in dual-axis and single-axis configurations and can be mounted horizontally or vertically. They are also available in intermediate ratios, as well as four- and five-speed transmission types. They can also be connected with additional output shafts.

Another type of worm gear reducer gearbox is the multi-stage variety. This gear reducer gearbox has multiple stages, enabling it to reduce speed with extremely low output speeds. In addition to the large transmission ratio, the multi-stage gear reducer gearbox has low noise, low vibration and low energy consumption.

Worm gear reducer gearboxes offer space-saving solutions as well as increased torque. Agknx Gearbox offers worm gear reducer gearboxes that solve common deceleration problems. The company has also expanded its product range into the bathroom market. Compared with the standard gearbox, the worm gear reducer gearbox has the characteristics of lower price and better torque output.

Agknx worm gear

The Agknx type worm gear reducer gearbox has multi-tooth line contact and is widely used in heavy machinery. These gears are characterized by a high load-carrying capacity, but they are highly sensitive to misalignment and manufacturing errors. However, by employing point contact, these gears can be made more reliable and can withstand higher loads.

Another major advantage of the Agknx worm gear is its high load capacity. The tooth profile design of the gears has a high relative slip ratio, which improves efficiency and load capacity. In addition, the large angle between the sliding direction and the contact line provides a low coefficient of friction. The Agknx worm gear also features premium carburized steel and phosphor bronze castings for exceptional durability. In addition, the tooth profile is very precise, the operation is quiet, and the speed fluctuation is small.

Agknx worm gear reducer gearboxes are designed to operate for up to ten hours per day with an even load. The design of this worm gear reducer gearbox stems from Sumitomo Heavy Industries’ extensive experience in gear reducer gearboxes. The smooth surface texture and precise tooth profile of the gears ensure that the gears can withstand high loads without damaging the lubricant film. In addition, Agknx worm shafts are specially designed to have the right stiffness.

Agknx worm gear reducer gearboxes are designed to maximize load capacity while minimizing energy consumption. Its fully meshed teeth reduce surface pressure on the worm gear teeth and increase load capacity. Double throat worm gear

Double throat worm gear

There are a few things to consider when choosing a dual-throat worm gear. First, the diameter of the root circle must match the circle pitch of the larger gear. This measurement is usually done by measuring the distance between adjacent teeth. Alternatively, the worm’s normal module can be used. It is the value entered in the worm module dialog. In addition, the axial pitch of the worm should be equal to the pitch diameter of the circular pitch.

Double-throat worm gears are an excellent choice for heavy and heavy-duty applications. The design of this worm gear is ideal for heavy-duty applications as it provides a tighter connection between the worm and the gear. It is also more compact than other types of gear and is comparable to a fine-pitch lead screw.

The efficiency of a double-throat worm gear depends on the material of the gear and worm. Typically, gears are made of case-hardened steel, while worm gears are made of bronze or cast iron. In some cases, a combination of cast iron and bronze can be used.

The deflection of the worm shaft is also affected by the tooth parameters. Tooth height, pressure angle, and size factors all affect the deflection of the worm shaft. In addition, the number of worm threads is another important parameter that affects the deflection of the worm shaft.

Double-throat worm gears are commonly used in industrial applications where high drive reduction is required. The worm has a concave and internal tooth structure that can be adjusted to achieve various ratios. Worm gears and worm gear assemblies must be properly mounted on their shafts to prevent back drive.

Brass worm gear

The basic working principle of the brass worm gear reducer gearbox is the same as that of the traditional worm gear reducer gearbox. Its axial pitch must be equal to the circumferential pitch of the larger gear. The single-thread design advances one tooth per revolution, while the double-thread design advances two teeth. The threads on the worm are either left-handed or right-handed. The lead of a worm is the distance a point on the thread of the worm moves in one revolution. The lead angle is the angle tangent to the pitch of the cylinder and the axis of the worm.

Double-thread worm gear reducer gearboxes are best for heavy loads. It provides the tightest connection between the worm and the gear. Assembly of the worm gear requires precise mounting. The keyway installation method involves drilling a square cut in the gear hole. This prevents the worm from rotating on the shaft and helps transmit torque. Then use the set screw to secure the gear to the hub.

The large fuel tank helps keep the worm gear clean and reduces heat. It also provides lubrication for extended life. Worm gear reducer gearboxes with oil reservoirs provide a lubricated environment and low-friction surfaces. Additionally, it offers multi-position installation flexibility. Additionally, its housing is cross-milled for precise alignment. It also features internal baffles for leak-free ventilation.

I260 series worm gear reducer gearboxes are one-piece iron casings with solid or hollow output shafts and tapered roller bearings. This gear reducer gearbox is designed for low to medium-horsepower applications. This gear reducer gearbox is a cost-effective option with low initial cost, the high gear ratio, and high torque in a compact package. Also, it is more shock resistant than other gear reducer gearboxes. Brass worm gear

Brass worm gear

Brass worm gear reducer gearbox is a reduction gear. This type of gear can provide a lot of reduction in a small package. This type of gear reducer gearbox also has the ability to generate high torque. However, it is important to understand that this gear reducer gearbox has thermal limitations, which reduce its efficiency. The choice of lubricant for this gear reducer gearbox is very flexible. However, being a yellow metal, it is important to remember that the lubricant must be non-reactive.

Worm gears are used in many consumer and industrial applications and have high reduction ratios. These gears are produced in various configurations and sizes. Worm gears are similar to spur gears but have non-parallel shafts. Worm gears are also suitable for applications requiring low output speed but high torque.

Worm gears have some distinct advantages over other gears. First, unlike standard gears, the worm rotates in a worm-like motion. This mechanism prevents reverse movement. This is because the lead angle of the worm gear is small. Additionally, the worms self-lock, helping to prevent reversal. However, this mechanism is not entirely reliable. Worm gears can be found in elevators, fishing reels, sprockets, and automotive power steering.

Another advantage of worm gears is that they are easy to manufacture. The rationale behind this design is to have two mutually perpendicular axes. Then, two or more threads are added to the worm gear. The common tangent between these two shafts intersects the pitch line of the worm gear shaft. This is the basis of transfer speed.

editor by CX 2023-04-17

in Barnaul Russian Federation sales price shop near me near me shop factory supplier Dynapac 4812045075 Spreader Drive Gearbox manufacturer best Cost Custom Cheap wholesaler

we have obtained the have faith in of purchasers worldwide. We are looking ahead to establishing profitable organization relationships with new consumers all around the world in the future. Our technicians and engineers have 23 years of Knowledge in the Bearing Sector. 4812035018

Dynapac 4812045075 Auger EPT

Ultimate EPT EPT for all the Asphalt Paver 4812571194 DYNAPAC 2530 EPT 4812571193 EPT CPL. 4812571194 EPT CPL

the EPT product you can choose:

–Volvo 8820,7820,6620,ABG423,ABG325,ABG525

–VOEPT, S1800, S1800-one,S1800-two,S2100, S2100-one.S2100-two, S2500.

–DYNAPAC, F141CS, F181CS,

—DEMAG:135CS, DG141CS, DF145CS

—EPT: WTU75, RP75, wtu95, WTU125, RP125, LTU125

—EPT: LTU90, LTU120

—EPT: LTU90, LTU120

one, excellent high quality

2, minimal cost, EPT EPT motor EPT

3, provide quickly

Our business can make EPT EPT in accordance to customer’ necessity.

HYDROTRAC GFT is an best driving part for wheel or observe driving automobiles, and other shifting equipment and widely used in excavator, EPTing EPT, drill EPT, cell crusher, engineering EPTry, mining, tunnel EPTry, agricultural EPTry, and so on. Meanwhile, diverse motor connectors and proportions are obtainable on request. It is an ideal substitution of EPT products.

Best China manufacturer & factory Agricultural Gearbox For Manure Spreader With high quality best price

Our company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country.

We also can design and make non-standard products to meet customers’ special requirements.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, farms

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- A worm gear system consists of a worm and worm wheel. The worm resembles a screw, which meets with a worm wheel, as shown in the photo. When rotational power is applied to the worm, it rotates against the wheel and transfers power to the worm wheel. The system is designed so that the worm can easily turn the gear, but the gear cannot turn the worm. In some designs, the friction between the gear and worm holds the worm in place. This feature can be very useful in some applications. Gearing Arrangement:

-

Bevel / Miter

- Output Torque:

-

–

- Input Speed:

-

–

- Output Speed:

-

–

Packaging & Delivery

- Packaging Details

- BOX

-

Lead Time

: -

Quantity(Units) 1 – 30 >30 Est. Time(days) 60 To be negotiated

Online Customization

Product Description

Agricultural Gearbox For Soil preparation

Gearboxes for machines used for small agricultural works, soil preparation and crop treatment.

Agricultural Gearbox For Manure Spreader

Manure Spreader Gearbox

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Related Products

|

Gearbox For Rotary Tiller |

Gearbox For Fertiliser Spreaders |

Agricultural Gearbox For HAY TEDDER |

|

Agricultural Gearbox For Rotary Cutter |

Gearbox For Rotary Mowers |

Agricultural Pto Gearboxes For Powered Generator |

|

Post Hole Digger Gearbox |

Gearbox For Self Loading Trailer |

General Gearbox For Agricultural Machinery |

|

Agricultural Gearbox For Manure Spreader |

Gearboxes For Silo Distributors System |

Driveline Motor Of Irrigation System |

|

Agricultural Gearbox For Fertilizer Spreader |

Hay Choppers Gearboxes |

Driveline Gearbox Of Irrigation System |

|

Agricultural Gearbox For Sprayers |

Gearboxes For Balers |

Center-Dive Gear Box Of Irrigation System |

|

Agricultural Gearbox For Flail Mower |

Gearboxes Multiplier For Hydraulic Pump System |

Hydraulic PTO Drive Gearbox Speed Increaser |

|

Agricultural Gearbox For Lawn Mowers |

Planetary Gearbox For Hydraulic Drive Digger In Line |

Side-Delivery Rake Gearbox |

|

Agricultural Gearbox For Generator |

Agricultural Gearbox For Harvest Fruits |

Planetary Gearboxes For Feed Mixer |

|

Agricultural Gearbox For Micro Tiller |

Gearbox For Cattle Cleaning |

PTO speed reducer |

|

Agricultural Gearbox For Concrete Mixer |

Gearbox For Digger Drive |

Slasher gearboxes |

|

Agricultural Gearbox For Feed Mixer |

Gearbox For Dryer Drive System |

Auger Gearboxes |

|

Agitators For Sewage |

Gearbox For Lagoon Pumps |

Grain Harvester Reversing Gearbox |

|

Salt Spreader Gearboxes |

Bevel Gearbox For Biogas Energy Generator Plant |

Oil-Pump-Gearbox |

|

Gearbox reducer for Climate screens drive system |

Gearbox For Circular Saw And Belt Saws |

Potato Harvester Gearbox |

|

Gearbox And Reducer For Crop Storage Drive Systems |

Gearbox For Snow Tillers |

Pesticide Sprayer Gearbox |

|

Gearbox Reducer For Horticulture Drive Systems |

Gearbox For Concrete Mixers |

Chain Sprockets Gearbox |

|

Drive Systems For Ventilation In Livestock FaOnce the PTO has begun to power the attachment, steadily increase the throttle until you reach the operating speed. The typical running RPM (revolutions per minute) for a tractor mounted PTO is 540 RPM, although there are tractor models that rev higher. Always refer to your particular tractor model for instructions prior to first-time use.rming |

Worm Gear Slewing Drive For Timber Grab |

Agricultural Gearbox Grain Conveyor Gearbox |

|

Electric Film Reeler Roll Up Units Winch For Poly Film Greenhouse Ventilation |

Agriculture Gearbox For Rotary Harrows |

Harvester Gearbox Reversing Bevel Gearbox |

|

Rotary Harrows Gearbox |

Agricultural Gearbox For Vineyard |

Reversing Gearbox |

|

Rotary Cultivators Gearbox |

Agricultural Gearbox For Weed Mowers |

Rotary Mower Gearboxes Size EP70 |

|

Gearbox For Trenchers |

Agricultural Gearbox For Offset Mowers |

Poultry and Pig Geared Motors For Feeding Systems |

|

Interpump Gearbox For PTO Drive |

Agricultural Gearbox For Flail Mowers |

Salt Spreader Sprocket Chain Gearbox |

|

Gearbox For Dusters |

Product packaging

Also I would like to take this opportunity to give a brief introduction of our Ever-Power company:

Our company is a famous manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported many products to our customers all over the world, we have long-time experience and strong technology support.

Some of our customer :

Italy: COMER,GB GEABOX ,SATI, CHIARAVALLI, AMA , Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies

Brazil: AEMCO ,STU

USA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-Ø Our Company with over twelve year’s history and 1000 workers and 20 sales.

-Ø With over 100 Million USD sales in 2017

-Ø With advance machinery equipments

-Ø With large work capacity and high quality control, ISO certified.

……

you also can check our website to know for more details, if you need our products catalogue, please contact with us.

Company Information